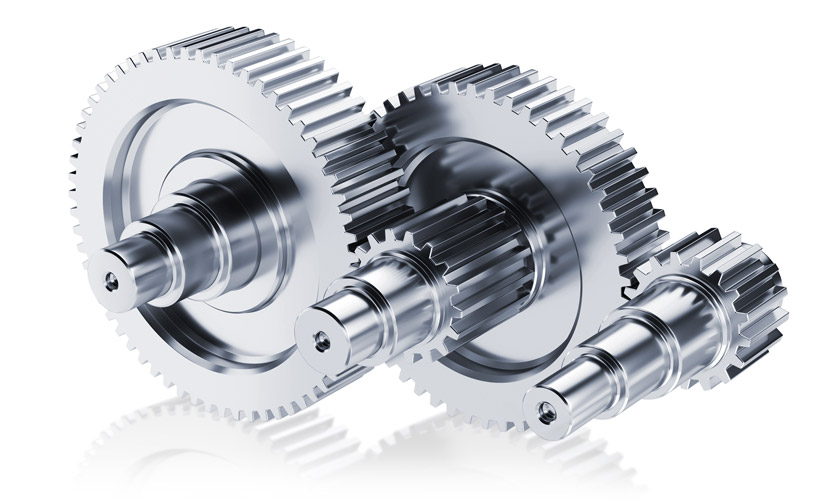

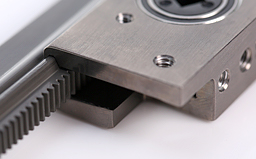

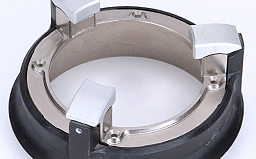

Precision manufacturing of robotics components and end effectors

Robotic-assisted surgery is on the cutting edge of technological advancements in medicine. ARCH Medical Solutions provides industry-leading expertise for manufacturing components, subassemblies, and end effectors for OEMs of surgical robotic systems.