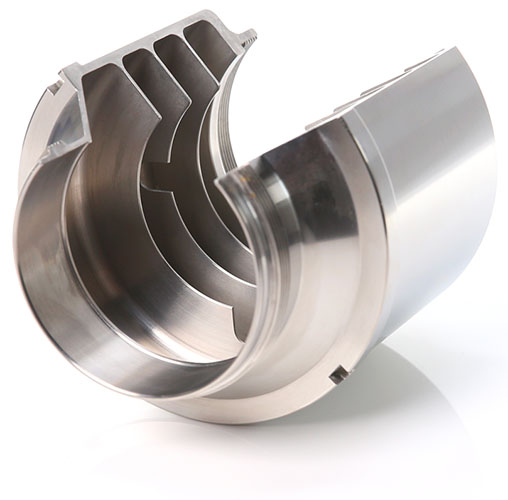

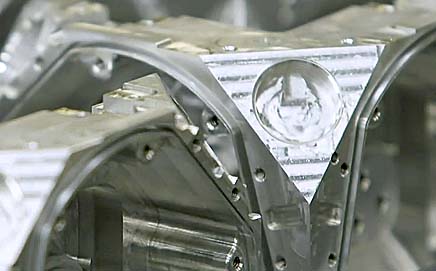

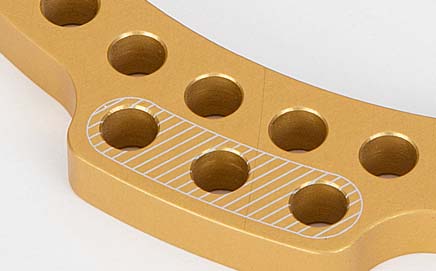

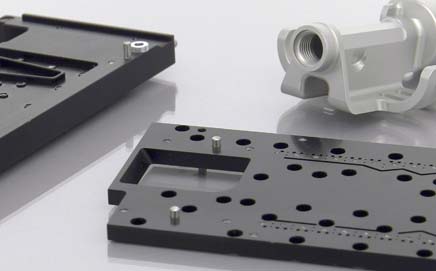

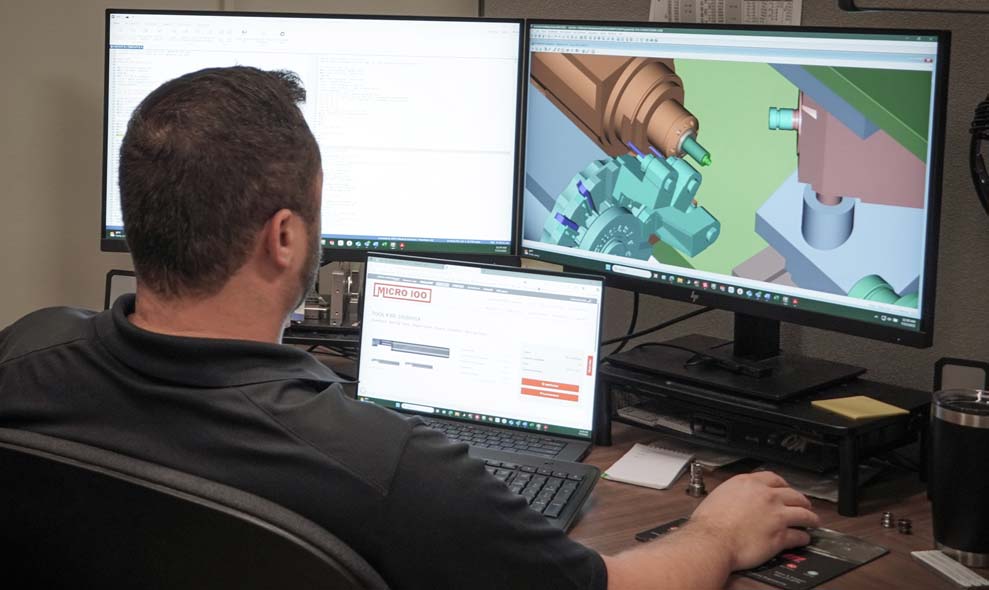

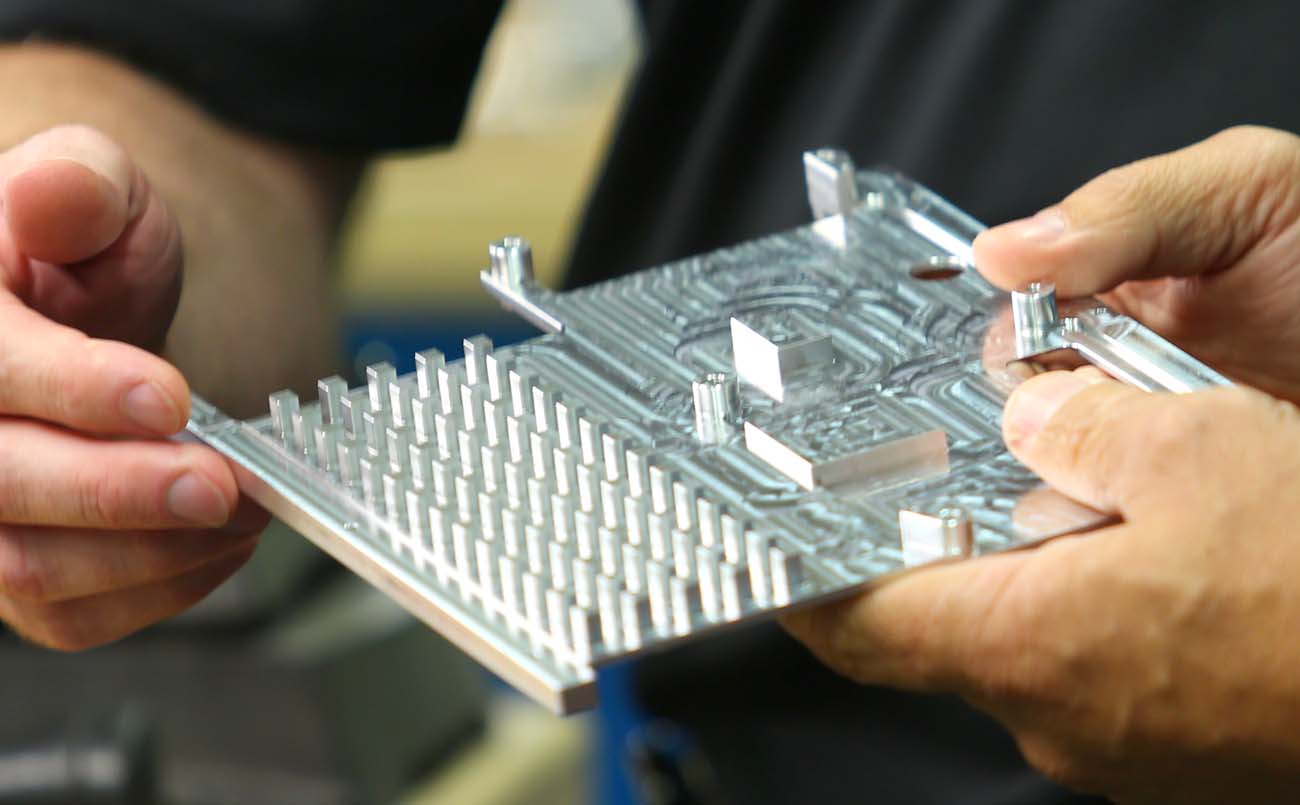

Collaborative engineering

Aerospace and defense OEM's need tailored solutions to achieve program success. By fostering a collaborative environment, we achieve superior performance and cost-efficiency for your precision-manufactured aerospace parts, components, and assemblies. We work with you to find solutions, providing a competitive edge through design collaboration, prototyping, and verification processes. We engineer not just your product, but the manufacturing method as well, placing you ahead of the competition. You benefit from shortened development cycles, reduced costs, and smoother transitions throughout the production life cycle.